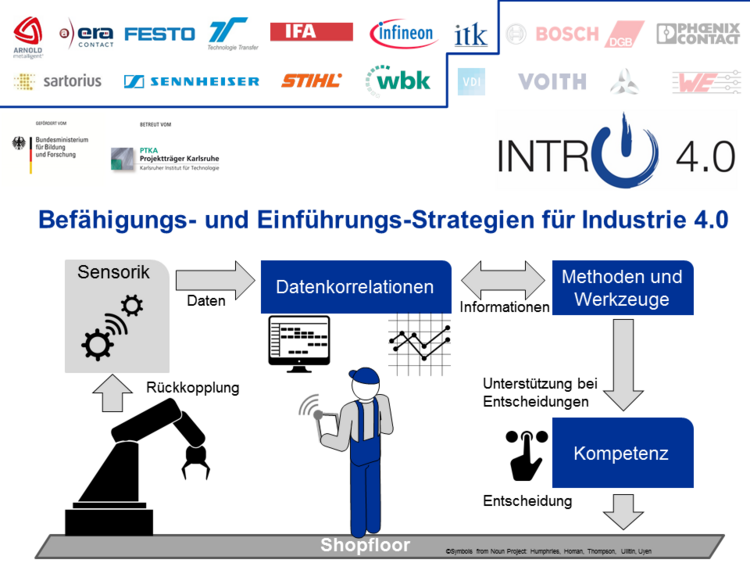

INTRO 4.0 - Capability and implementation strategies for industry 4.0

| E-Mail: | huebner@ifa.uni-hannover.de |

| Year: | 2016 |

| Date: | 01-01-16 |

| Funding: | BMBF |

| Duration: | 01.2016-12.2018 |

| Is Finished: | yes |

| Further information | http://www.intro40.de/ |

starting situation:

An efficient and goal-oriented introduction of information and communication technologies (ICT) into the factories of manufacturing companies promises huge productivity gains. Medium-sized companies in particular face major challenges in realizing these advantages. Insufficient resources and a lack of know-how make it difficult to introduce new technologies and methods to increase productivity in companies. Especially high investments in technologies are an obstacle for medium-sized companies. In addition, the introduction of solutions into a company at different stages of development, depending on the current "maturity level", is crucial in order to minimize financial and thus economic risks. Success-critical factors for the realization of empowerment and implementation strategies against the background of future expanding areas of responsibility are above all the qualifications and qualifications of employees and managers. They are to be understood as converters and users of industry 4.0 and beyond, as decision-makers in production.

goal:

Enterprises, especially SMEs, must be supported in the introduction of Industry 4.0 technologies. This ensures long-term competitiveness at the production site in Germany. For this reason, the project will develop strategies for enabling and implementing industry 4.0. The core elements that lead to a guideline for action can be summarized as follows:

- Procedure for risk and potential assessment during the introduction of industry 4.0

- Development of specific methods for increasing productivity in connection with the latest ICTs

- Procedure for risk and potential assessment during the introduction of industry 4.0

- Competence development concepts for employees and managers

- Quick check and maturity model to identify industry 4.0 potentials

- Competence development concepts for employees and managers

approach:

The research project is divided into 5 work packages:

work package 1: Recording of requirements and framework conditions

The task of work package 1 is to record the company's requirements for the implementation of the use cases and to take into account the prevailing framework conditions. Requirements from the area of data, IT architecture, competencies and processes have to be considered.

work package 2: Development of industry 4.0 methods

Work package 2 deals with the use cases. The user companies provide demonstration environments for this purpose. Specific Industry 4.0 methods are developed, tested and implemented on the real hall floor in cooperation with the experts. This means that the research results are implemented and tested directly on the hall floor. The use cases can be assigned to the following four areas:

- Development of methods for quality assurance and fault management (UC1)

- Development of methods for visualization (UC2)

- Development of methods for quality assurance and fault management (UC1)

- Development of methods for simultaneous engineering (UC3)

- Development of methods for robust logistics planning and control (UC4)

- Development of methods for simultaneous engineering (UC3)

The results of the use cases are proven industry 4.0 methods. These serve as storefront solutions, giving other companies access to the demonstration environments. The use of these methods is expected to increase productivity.

work package 3: Method for risk and potential assessment

In order to facilitate a target-oriented and sustainable integration of Industry 4.0 on the floor of the hall, Work Package 3 develops a procedure to estimate risks and potentials as well as the economic efficiency of the implementation of the developed Industry 4.0 methods for the company.

work package 4: competence development concept

In order to take account of the human factor and its special role in the targeted and sustainable introduction of industry 4.0, work package 4 elaborates a competence development concept for employees and managers confronted with industry 4.0.

work package 5: Maturity level-based action guidelines with generic toolbox

In order to bring together the results of the previous work packages, a maturity-based guideline for action is developed in work package 5. This guideline contains the capability and implementation strategies developed in the project and serves both to document and disseminate the results and findings. In addition to an extensible toolbox with Industry 4.0 methods, the guideline will contain a procedure for risk and potential analysis as well as a competence development concept. The development of a maturity model is planned for this purpose. The results and findings of the project are then translated into a maturity-based guideline for action.

basic data:

advancement: BMBF

promoter: PTKA Karlsruhe

duration: 3 years, 01.2016-12.2018

contact person:

Marco Hübner, M.Sc. huebner@ifa.uni-hannover.de

Dipl.-Wirtsch.-Ing. Norman Malessa malessa@ifa.uni-hannover.de